At HomeSquadz, we’re not just designing dreams; we’re meticulously building them, brick by precision-laid brick.

You’ve seen us kick off projects and establish the bedrock with initial foundations. Now, we’re thrilled to pull back the curtain further, sharing the intricate technical details and significant milestones achieved in recent weeks on our ongoing project . This is where your vision truly begins to take shape!

Phase 1: Solidifying the Substructure – A Foundation You Can Trust

While the initial footings are crucial, the subsequent phases are equally vital for a resilient home. Our focus on engineering excellence ensures every layer contributes to lasting stability.

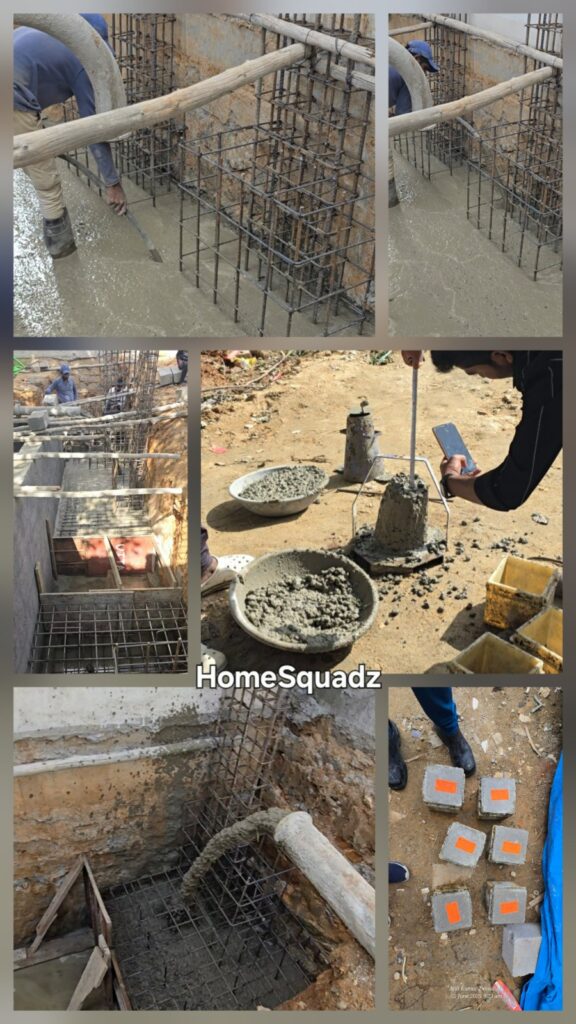

1. RMC Footing Pour & Rigorous Quality Control

On June 1st, we executed a precision Ready-Mix Concrete (RMC) footing pour. This wasn’t just about pouring concrete; it was a symphony of coordinated expertise. With two large RMC trucks on-site, our combined team – including HomeSquadz Site Engineer, Head Mason

Technical Spotlight:

- Slump Cone Test: Performed on-site to verify the workability and consistency of the concrete mix, ensuring it met specifications for optimal flow and compaction.

- Cube Test: Multiple concrete samples were collected and molded into standard cubes. These cubes are crucial for lab testing (typically at 7 and 28 days) to confirm the concrete achieves its designed compressive strength, ensuring the structural integrity of your foundation.

- Mechanical Vibration & Leveling: Immediately post-pour, high-frequency mechanical vibrators were used to thoroughly compact the concrete, eliminating any trapped air pockets and ensuring a dense, homogeneous structure. This was followed by precise surface leveling for a perfect base.

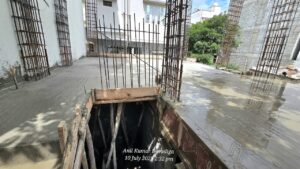

2. Deshuttering & The Science of Curing

By June 4th, the deshuttering of the footing and pedestal elements was successfully completed, revealing the perfectly formed concrete. The crucial process of curing then intensified. We understand that concrete gains its strength through proper hydration.

Technical Spotlight:

- Extended Curing: Our commitment goes beyond basic requirements. Curing, using clean water, is performed a minimum of three times daily, maintaining moist concrete surfaces for at least 7 days to promote optimal strength gain and prevent shrinkage cracks.

- Transparent Verification: To ensure adherence to these critical guidelines, our contractors upload geo-tagged videos for each curing session, allowing HomeSquadz engineers to remotely verify consistent and thorough hydration within the site radius.

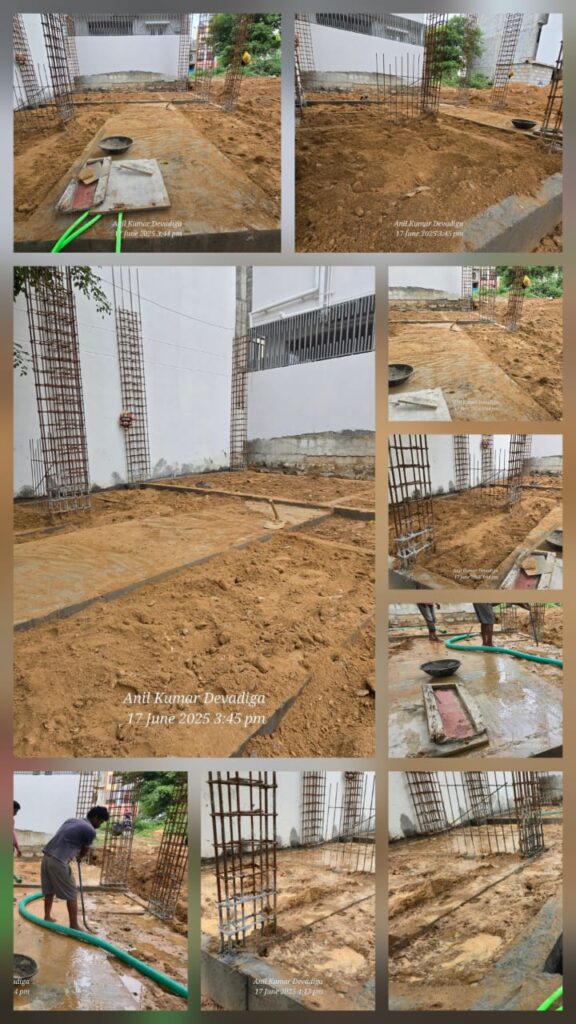

3. Strategic Soil Backfilling & Compaction

Following curing, meticulous soil backfilling around the completed footings was performed using a JCB. This isn’t just about filling holes; it’s about establishing long-term ground stability.

Technical Spotlight:

- Controlled Settlement: To achieve maximum compaction and natural settlement, approximately 11,000 liters of water were strategically released into designated settlement pits across the site. This process encourages natural soil consolidation, minimizing future settling issues.

- Safety First: Temporary guardrails were promptly installed by our site team, prioritizing safety during this phase.

Phase 2: Rising to the Skies – Plinth, Columns & Masonry Mastery

With the deep foundations solidified, we’re now bringing the structure above ground with precision and robust construction techniques.

1. Plinth Completion & Integrated Underground Utilities

Between June 9th and 19th, the plinth work reached completion – a vital horizontal structural element that distributes loads from the walls and columns to the foundations. This phase encompassed:

Technical Spotlight:

- Reinforcement & Casting: Exact bar bending and shuttering for the plinth beam, followed by a controlled concrete pour (completed on June 16th).

- Anti-Termite Fortification: A critical and often overlooked step, intensive anti-termite treatment was applied to the soil backfill using over 8,000 liters of water for deep penetration of the solution (e.g., Pidilite Terminator Structure Preservative). This proactive measure creates a chemical barrier, safeguarding your home from subterranean termite infestation.

- Seamless Utility Integration: All crucial underground work was finalized during this phase under strict HomeSquadz supervision. This includes the efficient drainage mainline setup using Supreme PVC Pipes, construction of robust inspection chambers, and the secure Kaveri water connection utilizing durable Ashirvad CPVC Pipes.

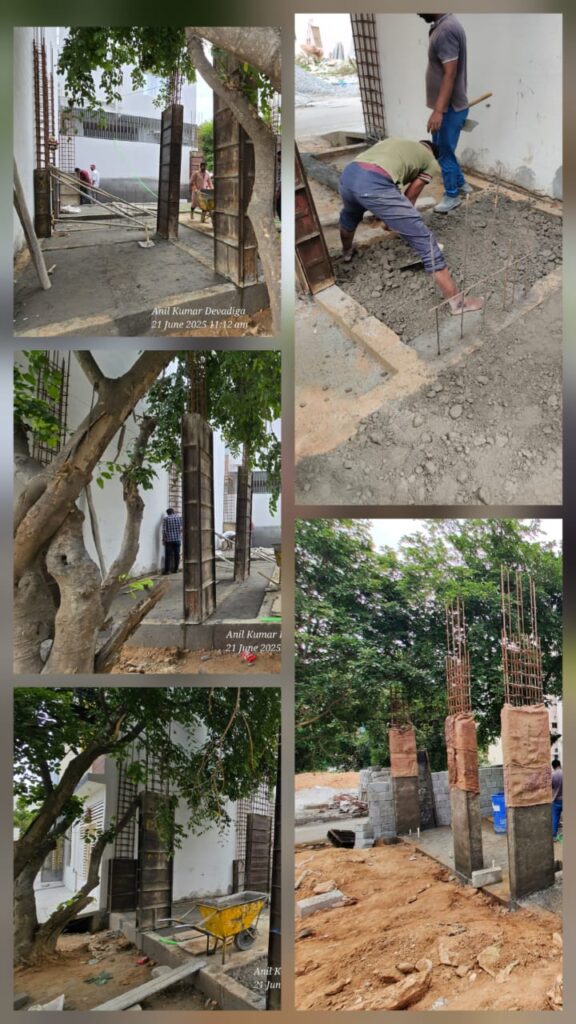

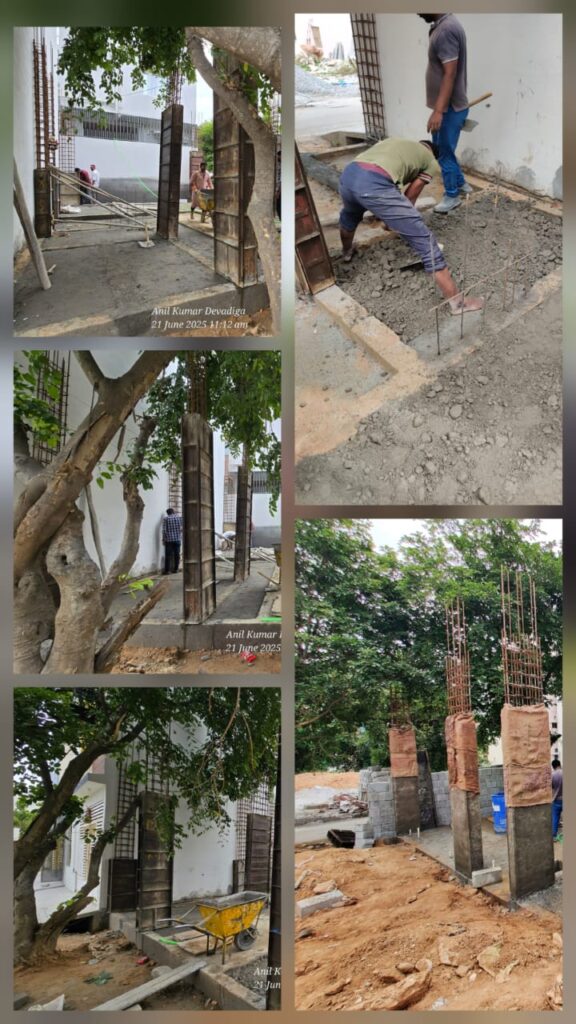

2. Column Work & First-Level Brick Masonry: Structural Artistry

The vertical ascent is impressive! Our team completed column and floor PPC concreting ahead of schedule on June 21st. We ensure the strength of these vertical supports through:

Technical Spotlight:

- High-Strength Concrete: Utilizing M25 grade concrete with a precise 0.5 water-cement ratio for superior durability and load-bearing capacity.

- Diligent Curing: Our commitment to concrete strength extends to columns, with consistent curing performed four times daily using a 1HP Sharp water pump for uniform hydration.

- Precision Masonry: The first level of brick masonry above the plinth beam is now complete, using high-quality concrete blocks for uniformity and strength. We adhere to exact specifications: a 1:6 cement-to-sand mortar mix and a consistent 10 mm joint thickness, crucial for structural integrity and aesthetics.

- Multi-Point Quality Checks: Before moving to the next level, our site engineers perform rigorous internal alignment checks, plumbing rough-ins verification, and electrical conduit provision checks, ensuring everything is perfectly aligned with design.

3. Staircase, Lintel & Upcoming First Floor Work: Reaching New Heights

The structure is now rapidly gaining height, preparing for the next floor.

Technical Spotlight:

- Complex Formwork: Shuttering for both the staircase and lintel beams (which support openings over doors and windows) is a critical current activity, requiring precise carpentry and structural alignment.

- Optimized Design Implementation: Based on a practical, on-site recommendation from our Head Mason Dhananjay, and meticulously reviewed by Site Engineers Uday and Prashant, the entrance height has been intelligently adjusted from 6 feet to 7 feet. This small but significant change eliminates potential headroom issues and significantly improves overall accessibility and comfort for the homeowner.

- Next Steps: Lintel casting is targeted for completion next week, quickly followed by the start of first-floor molding work.

At HomeSquadz, every technical detail, every quality check, and every innovation on-site is driven by our commitment to delivering your dream home, built on a foundation of trust and engineering excellence. We are proud of our teams’ dedication and the transparent progress we’re able to share with you.

Stay tuned for more updates as we continue this incredible journey, turning blueprints into vibrant living spaces.

Ready to see your dream home take shape with HomeSquadz? Contact us today to learn more about our projects and discover the HomeSquadz difference!